Given that its inception, printmaking has revolutionized the globe as we know it. It gave writers, publishers, and artists the edge of producing copies. In switch, it uncovered far more men and women to their perform speedier. Some of the earliest printing solutions were utilized in China all-around the 9th century, which involved making use of hand-carved blocks. In the 15th century, the Gutenberg push manufactured printing on a mass scale more quickly than past strategies. In the electronic age, we may get the thought of earning several copies of a little something for granted mainly because we can have it with a rapid scan or a click on.

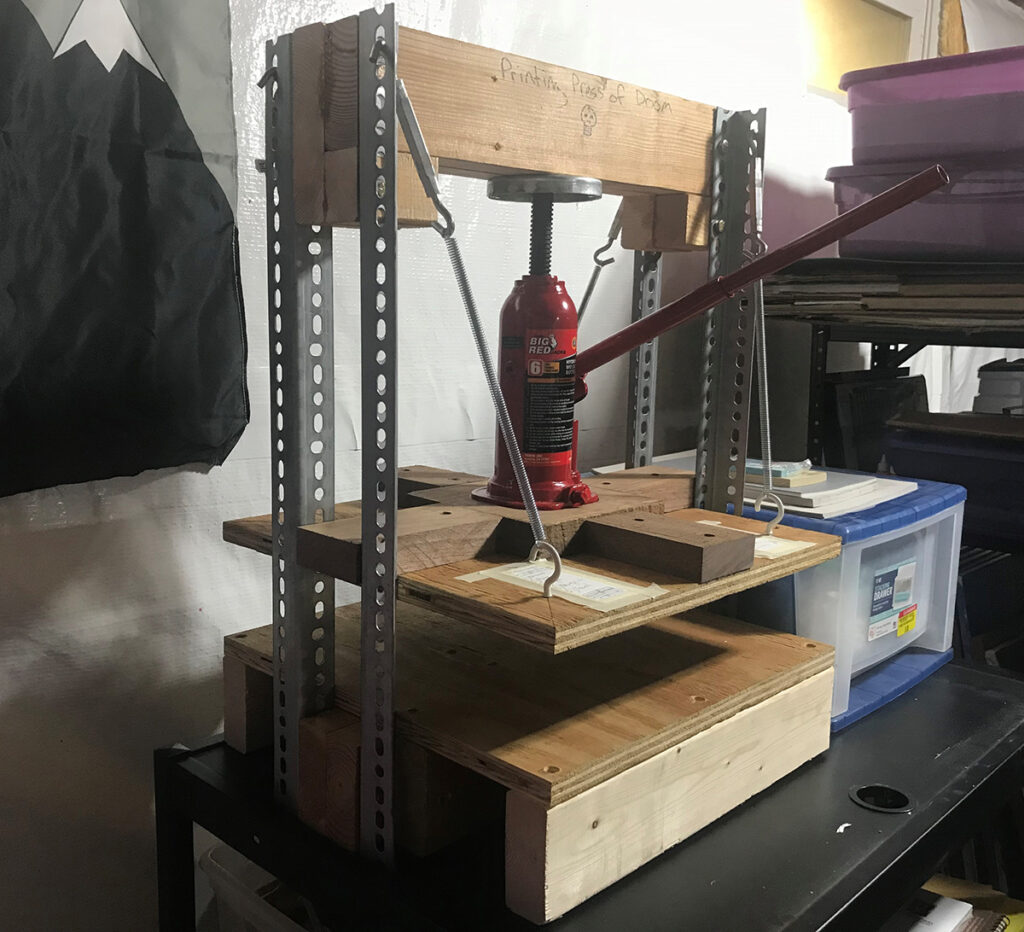

Do not underestimate the printmaking system. Exposing youngsters to this artform is exciting and opens the door to numerous creative prospects. Lots of artwork academics choose for hand printing procedures for the reason that they do not call for a push. If you are privileged to have obtain to a printing press in your studio, look at you one particular of the fortunate several. If you are looking for an very affordable push, with a several straightforward hand and electrical power equipment, you can construct your possess applying an automotive bottle jack.

Dependent on the prices of regional resources, you can create this push for $100–$300. In comparison, most suppliers have etching or platen-design presses for hundreds if not thousands of pounds more. The most highly-priced purchases for this Do-it-yourself are the automotive bottle jack and slotted steel. If you are thrifty, you can buy a bottle jack 2nd-hand as extensive as you assure it does not leak and the piston goes up and down smoothly. A six-ton jack really should suffice for all of your classroom printing needs. If you have to have anything even larger, it will need taller slotted metal, which expenditures a lot more. Nearly anything scaled-down than three-ton may perhaps not give ample stress for selected print varieties.

Another point to think about is if your faculty district can set the revenue for this develop into your artwork budget. If you have to pay back out of pocket, inquire about a reimbursement program. Applying for a grant is an additional possibility to try out.

Let us search at the materials you will require for this build:

Here’s a record of applications you will want:

- Round, miter, or radial arm observed (a handsaw will function as well)

- Drill and influence driver with bits

- Tape measure

- Wooden clamps

- Wooden glue

After you have gathered all of your materials and instruments you are completely ready to make! The video clip, How to Establish a Bottle Jack Press Demo, is exceptionally valuable in visualizing the push and measures. Hold in thoughts you can modify this in any way to in good shape your desires!

Below are 10 measures to make your bottle jack printing push.

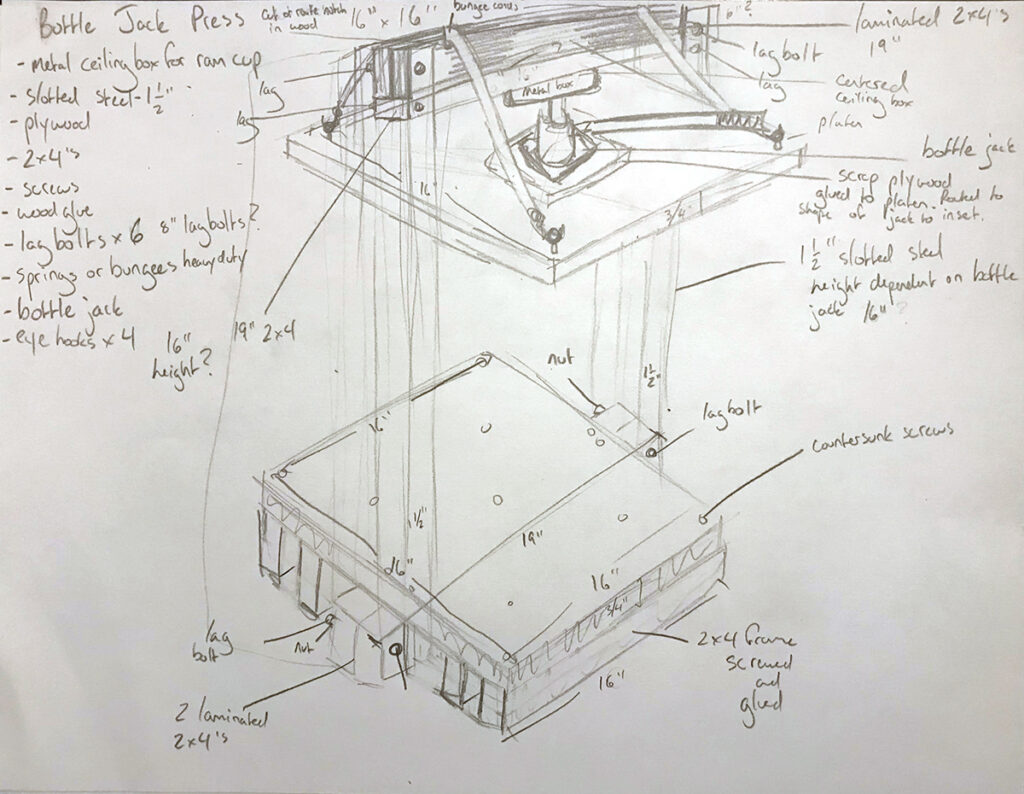

1. Make a sketch and diagram for your establish.

Ascertain all the dimensions and dimensions of your push like the width, size, and top. Keep in intellect to maintain items reasonably smaller sized, even with a six-ton push. It is advisable not to exceed a 20″ width or length on the foundation.

2. Cut 2 2 x 4s for the header and then glue and clamp them together.

The moment dry, established the header piece aside for later on. Make sure it sticks out extended plenty of to attach to the slotted metal for a afterwards move.

3. Lower 2 2 x 4s for the center of the foundation and then glue and clamp them alongside one another.

Right after it dries, this will be the heart of your press base. Assure it sticks out long plenty of to connect to the slotted metal for a afterwards step.

4. Reduce and screw the 2 x 4s to frame out the press foundation.

Use the laminated 2 x 4 in the center of your foundation. Use other 2 x 4s to make a framework for the major of the foundation.

5. Cut and screw the plywood for the prime of the base.

Screw the plywood appropriate on top of the 2 x 4 foundation. It is encouraged that you countersink your screw heads so they do not exhibit up on a ultimate print.

6. Set up the slotted metal on each side of the laminated foundation and insert the laminated header for the major. Then, drill holes and insert the hex bolts.

This section can be tricky so use a wooden clamp or two to keep the steel in location while you drill and generate your hex bolts. If you do not have an influence driver for the bolts, you can use ratchets and a wrench to safe them in location. Make certain it is comfortable!

7. Connect the metallic electrical box to the header.

Come across the dead-center of your header and screw in the metallic circle or electrical box. This serves as a ram cup for your press so it does not dig into the wood about time.

8. Reduce a piece of plywood for the platen pressboard.

Make guaranteed the platen push board is the very same size as your plywood base.

9. Screw 4 eye hooks on to the platen pressboard. Then connect bungee cords or turnbuckles and springs to the header and eye hooks.

10. Locate the useless-centre of the platen board and put the bottle jack in the heart.

It is a good idea to make some form of foundation for the bottle jack so it does not slide about throughout use.

Let us seem at the procedure of the push.

- Location your jack on the centre of your platen board.

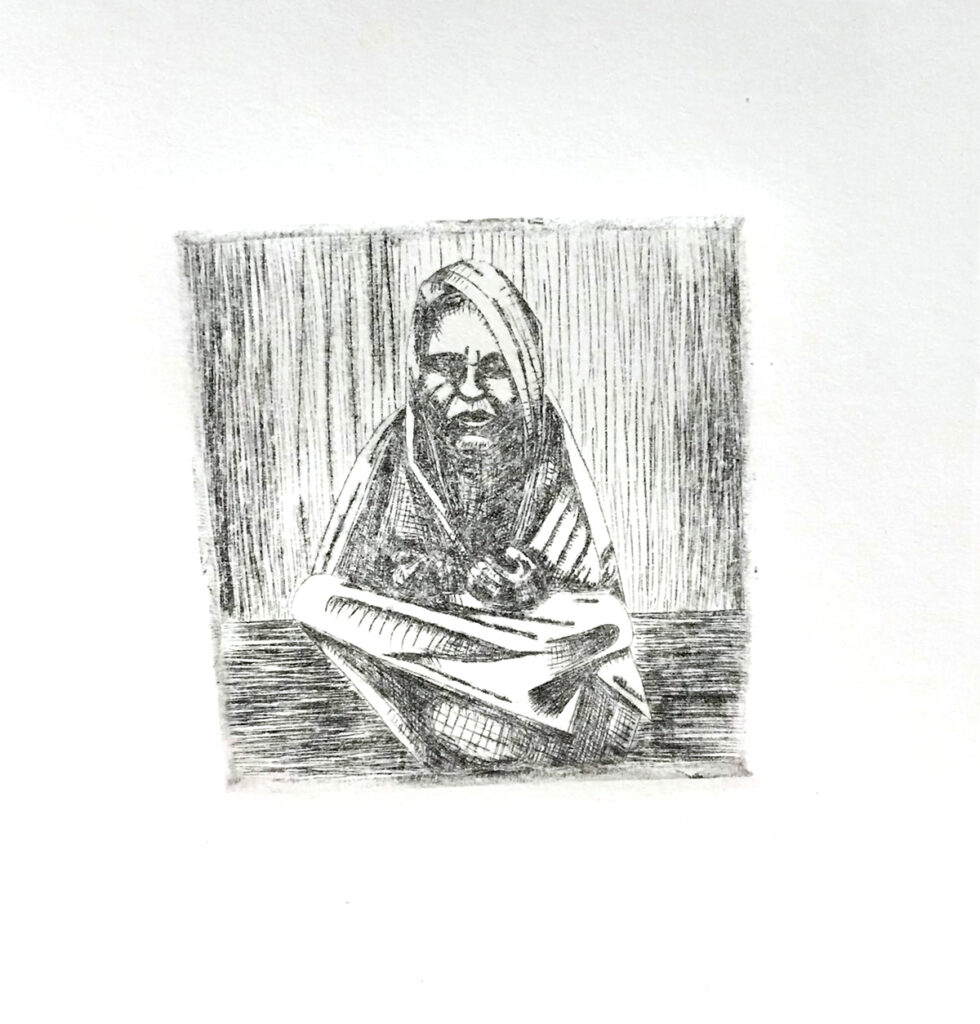

- Established up your print. It may possibly search marginally distinct based on what style of print you are creating.

For linocut prints, place a piece of tagboard on the base, the inked block, then the paper.

For etching or intaglio prints, place a piece of tagboard on the base, the inked block, printing paper, butcher paper, then a folded towel. - Work the jack as ordinary. (Consult your owner’s guide for your certain design.) Most jacks are the identical. Tighten the valve, insert the handle into the piston cup, and pump the piston to raise the jack. In this circumstance, raising the jack closes the gap between the platen board and the foundation.

- Pump the jack until finally the platen or prime board thoroughly fulfills your print, and you can not pump any more. Be cautious not to overpump your jack, or a catastrophic failure can occur, these kinds of as your header board cracking. Remember, these jacks raise automobiles, so it has extra than adequate tension to make your prints!

- After you cannot pump the push any longer, launch the valve on your push, which should result in the platen board to increase. Slide out your print and admire it!

This selfmade press does take some follow to use and wonderful-tune. Use it as a trainer-guided station or for demonstrations in an elementary location. In center or superior college, consider exhibiting your students how to use the push and heart it around a printmaking task of your alternative. This push can also deal with some bookmaking or embossing assignments. Get some resources and get begun creating this bottle jack push. The sooner you develop it, the sooner you and your pupils can use it!

If you are looking for printmaking classes and sources, look no further more!

How can you see you employing this Do it yourself push in your classroom?

Do you have any modifications or modifications you would make to this develop? If so, what are they?